Build Your Future

From Vision to Reality

Tag along as I stumble through the trials and tribulations of building a custom net-zero house in beautiful Point Roberts, WA with minimal experience and a relatively modest budget.

OR Start From The Beginning

Where are you going to build your dream home? For myself, it was important to locate a site where I could find affordable land near a large city. Luckily for me, I was able to find the perfect spot. An affordable, reasonably sized plot near the beach just a half hour away from one of my favorite cities in the entire world. It was a stroke of luck... Read More

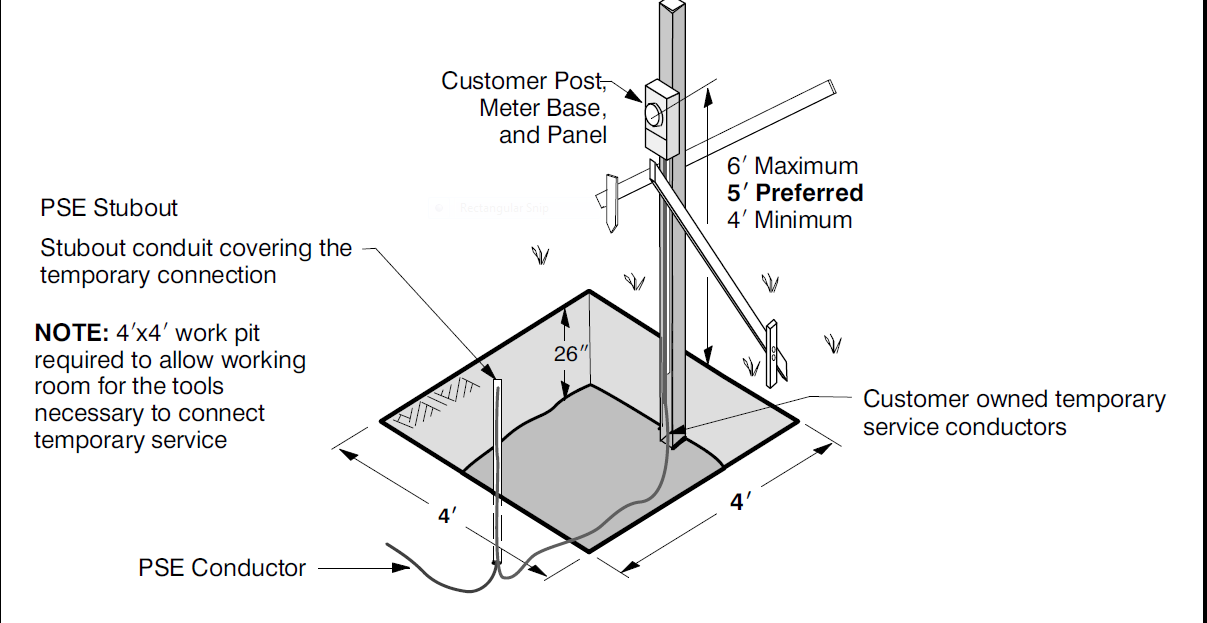

The requirements for this step will certainly vary widely, but it basically involves getting all of the services you need to use while you are building. I will be living on my lot at the same time as I am building so I'm going to need more services to start than someone who has a home away from their lot. In addition... Read More

There are many reasons why I need to get some electricity running at the lot as soon as possible. It will power my tools. It will power the lights and heat in the trailer I will be living in. It will charge my phone and computer. It will even power the pump that will run the septic system. In short, living without electricity is awful. Did you know... Read More